Temperature Cycling is performed as part of the semiconductor package qualification process to determine the ability of components and solder interconnects to withstand mechanical stresses induced by alternating high and low temperature extremes. Permanent changes in electrical and/or physical characteristics can result from these mechanical stresses.

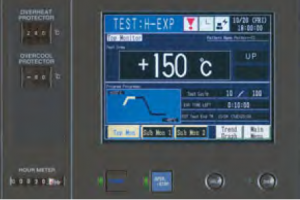

Reltech provides a full capability for Temperature Cycle testing as part its full turn-key solution to package level qualification testing. Our Temperature Cycling system type Espec TSA11-A, two zone (-65°C to +200°C) vertical movement system, provides an exceptional recovery time of less than 5 minutes without the need for any auxiliary cooling. The system incorporates a soft move feature reducing any vibration shock to the devices under test when moving the devices from the high temperature zone to the low temperature zone. A uniform temperature distribution ensures consistent stress at all times.

- JEDEC Standard JESD22-A104 and MIL-STD-883E Method 1010.7 compliant

- -65°C to +200°C capability

- Two temperature zone system capability

- Recovery time – less than 5 minutes in either zone

- Soft move feature reduces vibration shock on devices under test

- Programmable soak mode

- Full test data logging and reporting

- All package styles accommodated.