Each analysis can be specified for 3 levels of detail, depending on time-line and budget.

Basic – an initial investigation to check specifically defined elements are in order.

Intermediate – more in depth investigation checking the specifics of the product in line with the specifications stated.

Detailed – a more involved investigation to identify the route cause of a specific problem.

We are happy to offer cost-free initial consultancy to select your optimized work flow.

- Ext Visual examination

- Build a test socket board

- Electrical benchtop testing (Basic)

- Xray package analysis

- CSAM package analysis

- Decapsulation (inc. Cu w/laser, polyimide, MEMS Gels)

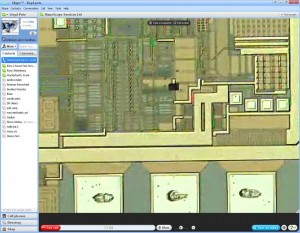

- Internal optical inspection (inc.bonding)

- Anti-counterfeit check (partnered with ELTEK)

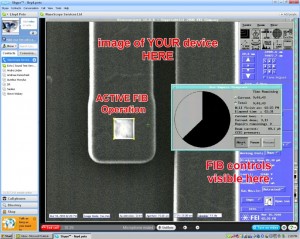

- FIB/SEM internal inspection

- Adding FIB probe pads (electrical debug)

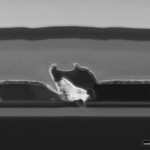

- FIB sectioning and imaging (w/wo iterative slicing)

- Process Metrology (inc. SI/SE imaging)

- SEM EDS studies

- FIBxTEM Sectioning, extraction and TEM imaging with EFTEM elemental analysis options

- Report