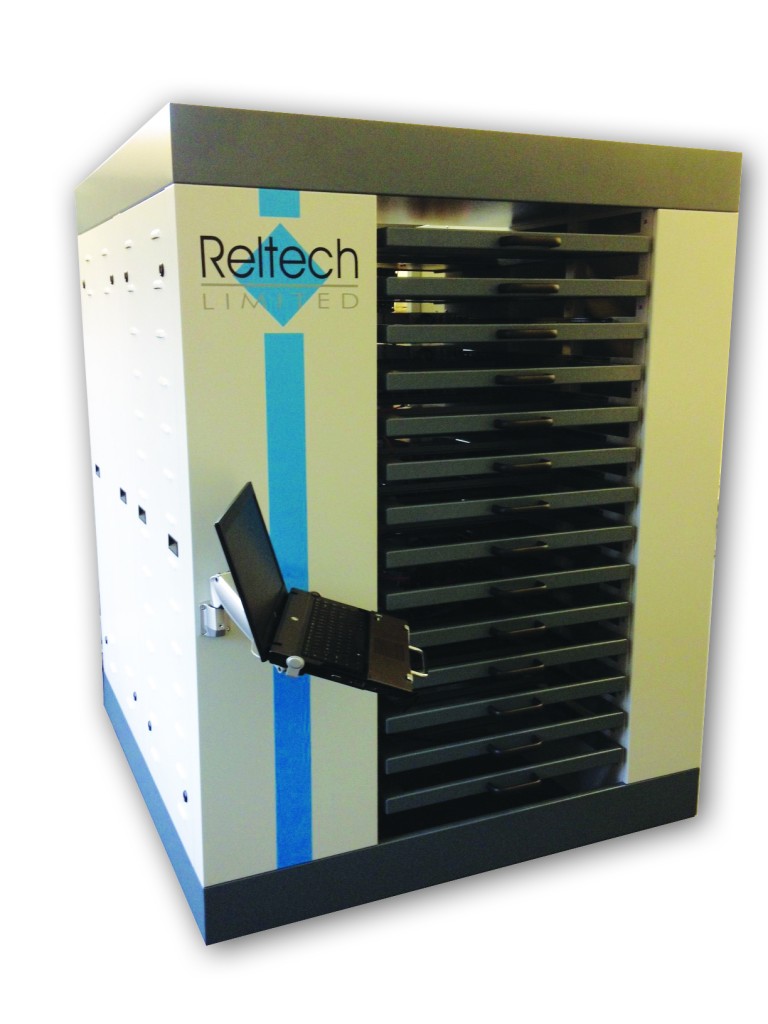

Today’s low geometry semiconductor devices require a different approach to performing High Temperature Operating Life (HTOL) and “Burn-In”. Core Leakage currents vary greatly between device die, even when from the same wafer, and are significantly higher than those of larger geometry devices. These leakage currents result in self-heating within the device and increased junction temperatures (Tj). In order to control the junction temperature to within acceptable limits and to increase product yield, it is necessary to control the temperature of each device independently. This is not possible in conventional chamber based HTOL systems. The Reltech independent Test Laboratory is pleased to announce the latest addition to its portfolio of semiconductor qualification test systems. The Reltech 8000 series HTOL system incorporating iSocket™ technology, provides the highest level of thermal control possible for High Temperature Operating Life Testing and Burn-In of the very latest low geometry, high power semiconductor devices.