Reltech HTOL systems – changing concepts

- With ever decreasing geometries, the way we perform HTOL requires careful consideration.

- In lower geometry device leakage currents are not only higher but vary greatly.

- Temperature control at DUT level – required to achieve correct junction temperature at every DUT.

- For higher geometries, HTOL can be performed in a more traditional way but with devices consuming more power, the ambient temperatures required varies greatly.

- Multiple temperature zones are required – multi zones system or multiple smaller HTOL systems.

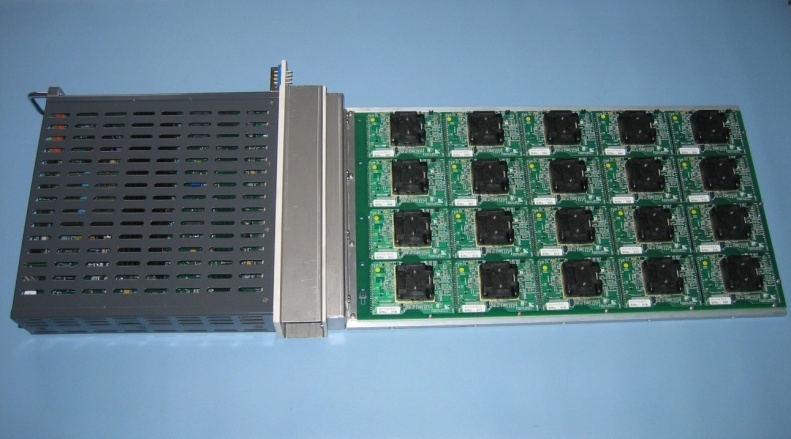

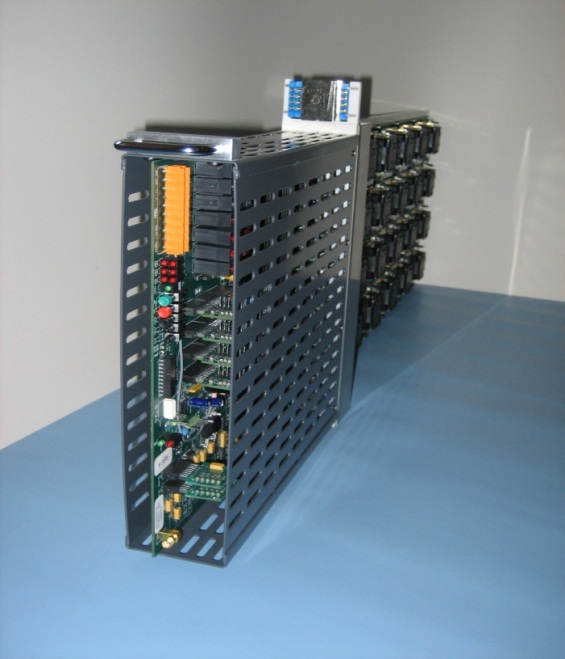

Reltech 7121 HTOL system

- 21 HTOL Trays per chamber

- 2.5m/s airflow high power

- < 5W HTOL application

- Up to 5 HTOL Lots per chamber

- 192 I/O’s per Tray

- 5 voltage rails per tray

- Easy access to Driver Card at front of chamber

- Lattice front – flexible load/unload timing

- Driver Cards – Digital/Analogue/Mixed signal

- Standard or application specific

- DUT monitoring and logging via PC and MIDAS software